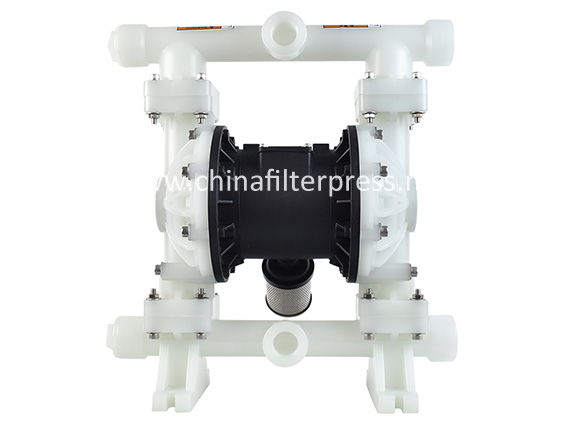

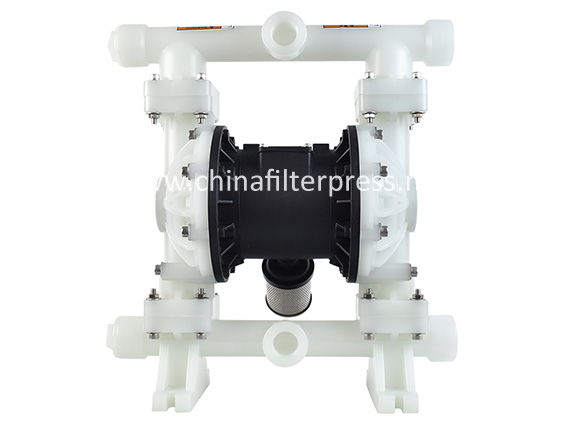

Pneumatic diaphragm pump is a new type of conveying machine that uses compressed air as its power source. It can completely pump out all kinds of corrosive liquids. It can be placed in various special occasions to pump various media that conventional pumps cannot pump.

Pneumatic diaphragm pump is a new type of conveying machine that uses compressed air as its power source. It can completely pump out all kinds of corrosive liquids. It can be placed in various special occasions to pump various media that conventional pumps cannot pump. It can also be divided into cast iron, stainless steel, aluminum alloy, fluoroplastics, etc. according to user requirements.

Compressed air drives the diaphragm to perform reciprocating motion, thereby achieving the suction and discharge of liquid. The Pneumatic diaphragm pump is mainly composed of two symmetrical working chambers, each of which is equipped with an elastic diaphragm, and the two diaphragms are connected together by a connecting rod. When compressed air enters the air distribution valve, it pushes one side of the diaphragm to move outward, while the other side of the diaphragm moves inward, forming a pumping action.

1. No need to pour water, the suction distance is up to 5m, the head is up to 70m, and the outlet pressure is ≥6bar.

2. The flow is wide and the performance is good, and the maximum particle diameter allowed to pass is up to 10mm. When pumping mud and impurities, the wear on the pump is very small.

3. The head and flow can be adjusted steplessly through the opening of the air valve (the air pressure is adjusted between 1-7 bar).

4. No electricity is required, and it is safe and reliable to use in flammable and explosive places.

5. It can work immersed in the medium.

6. Easy to use, reliable operation, and start and stop only need to open and close the gas valve.

7. It can transport more viscous liquids (viscosity below 10,000 centipoise).

8. This pump does not need to be lubricated with oil, and even if it is idling, it will not have any effect on the pump. This is the biggest feature of the pump.

Pneumatic diaphragm pumps are widely used in industrial fields that require both performance and easy maintenance, such as fine particles, high viscosity, volatility, flammability and explosion, strong acid and alkali, corrosiveness and other demanding industrial occasions. They are also suitable for food, medicine, tunnel engineering and other fields. Stable directional liquid transportation is widely recognized and used.

| Type | Max. Flow rate (L/min) | Max.Discharge pressure (Bar) | Sucked lift (m) | Max. Grain diameter (mm) | Max.air consumption (L/min) |

| QBY10 | 16 | 6.9 | 5 | 1 | 300 |

| QBY15 | 20 | 6.9 | 5 | 1 | 300 |

| QBY25 | 100 | 6.9 | 5 | 2.5 | 600 |

| QBY40 | 140 | 6.9 | 5 | 4.5 | 600 |

| QBY50 | 240 | 6.9 | 5 | 8 | 900 |

| QBY65 | 280 | 6.9 | 5 | 8 | 900 |

| QBY80 | 400 | 6.9 | 5 | 10 | 1500 |

| QBY100 | 480 | 6.9 | 5 | 10 | 1500 |