Automatically pull plate filter press with PLC control, can operate filter press (such as compression plate, bomb door openand close, pull plates), and left the remote control interface, to remote automatic operation control.

Filter press is an industrial equipment specially used for separating solid and liquid. The machine can be equipped with multi-layer filter plates. After the adjacent filter plates are equipped with filter media, a filter chamber is formed in the middle. Different filter chambers are connected. In the compressed and closed state, each filter plate injects the slurry to be separated from the feed inlet through the feed pump, and the slurry fills each filter chamber of the filter press. The liquid permeable filter medium (usually filter cloth, filter paper plate, etc.) flows out through the liquid outlet, and the solid is intercepted by the filter medium in the filter chamber to form a filter cake, The filter chamber can be easily opened to remove the filtered solids (i.e. filter cake), and the filter medium can be easily cleaned or replaced.

Filter press is a solid-liquid separation equipment for intermittent filtration, but its performance is stable and reliable, especially when the ratio of residual liquid in solid is very low. In the process of wide application of filter press, the final choice between separated solid and liquid varies greatly in different industries. Some are to obtain higher purity solid, or dissolve the content in the liquid after solid-liquid mixing, and then separate it after solid-liquid separation, some are to reuse the water in the mixture, and others have application requirements for separated solid and liquid, etc, Filter press is a good choice.

The filter press is composed of frame, filter plate, pressing system (manual, mechanical, hydraulic and other types) and electrical control system. The frame part plays the role of supporting the pressing device and filter plate, and is composed of base, pressing plate, thrust plate and main beam. The filter plate is installed on the main beam between the compression plate and the thrust plate, and filter media such as filter cloth are installed in the middle of the filter plate.

In 1853, the filter press was invented in England for oil filtration. The main development of filter press technology began in the middle of the 20th century. In 1958, the Japanese successfully developed the world's first automatic horizontal filter press to improve the removal efficiency of filter cake and reduce the moisture content of filter cake. Later, a diaphragm filter plate filter press was developed in Japan to reduce the moisture in the filter cake. The advantages of diaphragm filter press increase the opportunities of filter press in various industrial applications. Filter presses were often used to extract sugar from sugar beets and sugarcane and to dry pulp in the late 19th century and beyond. Now, the world's largest filter press manufacturing base and application market are in China.

The basic types of filter press include: plate and frame filter press, chamber filter press, membrane filter press, etc. According to the different compression methods and automation, the types of filter presses include: program-controlled automatic plate pulling filter press, hydraulic compression filter press, mechanical compression filter press, Jack compression filter press, manual screw compression filter press, etc. If different filter plate materials are considered, the filter press can also be divided into PP filter plate filter press, cast iron filter plate filter press and stainless steel filter plate filter press.

Filter presses have a variety of applications, from pulp dewatering to plasma purification. At the same time, filter press technology is widely used in ultra-fine coal dehydration and filtrate recovery in coal preparation plants. The industrial applications of automatic diaphragm filter press include dewatering of municipal sewage sludge, recovery of ready mixed concrete water and recovery of metal concentrate. Box filter press is widely used in saccharification operation because it provides very high efficiency and reliability. It is popular in maple syrup production in Canada and sugar beet and sugarcane production in countries such as Pakistan and Indonesia.

Filter press is also widely used in food, beverage, wine making, medicine, oil, chemical industry, papermaking, printing and dyeing, coating, electroplating, ceramics, leather and industrial sewage treatment.

Currently, the filter plate of filter press is made of polymer or polymer coated steel. According to the needs, the filter plate can also choose cast iron or stainless steel materials, which provide a good drainage surface for the filter cloth. The size range of the filter plate is 250 ×250 mm to 2.0 × 2.0 meters, and larger or smaller sizes are available.

Filter press usually uses filter cloth as filter medium, which is made of polypropylene filter cloth, non-woven fabric, cotton cloth, etc. filter paper board, cotton pulp board or filter membrane can also be used as filter medium as required. Generally, the cake thickness of plate and frame filter press can reach 50 mm, but in extreme cases, it can be increased to 200 mm. The box filter press (concave filter press) can form a filter cake with a thickness of 30-40mm.

Before using the filter press for filtration, if the solid suspension has precipitated, the mixed liquid needs to be pretreated, which can improve the performance of the filter press because it increases the porosity of the filter cake, thus speeding up the filtration speed. The size of floc can be controlled by changing temperature, concentration and pH value. In addition, if the filter cake is impermeable and not conducive to the flow of filtrate, filter aids can be added in the pretreatment process to increase the porosity of the filter cake, reduce the resistance of the filter cake and obtain a thicker filter cake. However, the filter aid needs to be able to be removed from the filter cake by physical or chemical treatment. A common filter aid is diatomite, with a porosity of 0.85.

Automatic rapping device, quick opening unloading device, automatic warping of filter cloth, automatic cleaning device of filter cloth, automatic bomb door, filter cake conveyor, mud storage bucket, etc.

Feed pump, cleaning pump, mixing drum, pipeline and valve, air compressor, air storage tank, etc.

| Type | Filter area(m2) | Filter plate size(mm) | Filter cake thickness(mm) | Filter chamber volume(L) | Filter plate number (PCS) | Filtrating pressure(Mpa) | Motor power(KW) | Machine Dimension(mm)(LxWxH) |

| XZ30/870-30U | 30 | 870x870 | 30 | 460 | 23 | 0.6 | 2.2 | 3180x1200x1300 |

| XZ40/870-30U | 40 | 595 | 30 | 3570x1200x1300 | ||||

| XZ50/870-30U | 50 | 748 | 38 | 4110x1200x1300 | ||||

| XZ60/870-30U | 60 | 902 | 46 | 4550x1200x1300 | ||||

| XZ70/870-30U | 70 | 1056 | 54 | 4990x1200x1300 | ||||

| XZ80/870-30U | 80 | 1210 | 62 | 5430x1200x1300 | ||||

| XZ50/1000-30U | 50 | 1000x1000 | 752 | 28 | 0.6 | 4 | 4040x1500x1400 | |

| XZ60/1000-30U | 60 | 914 | 34 | 4460x1500x1400 | ||||

| XZ70/1000-30U | 70 | 1063 | 40 | 4760x1500x1400 | ||||

| XZ80/1000-30U | 80 | 1219 | 46 | 5120x1500x1400 | ||||

| XZ100/1000-30U | 100 | 1505 | 57 | 5780x1500x1400 | ||||

| XZ120/1000-30U | 120 | 1816 | 69 | 6500x1500x1400 | ||||

| XZ100/1250-30U | 100 | 1250x1250 | 1479 | 36 | 0.6 | 4 | 5020x1800x1600 | |

| XZ120/1250-30U | 120 | 1777 | 43 | 5470x1800x1600 | ||||

| XZ140/1250-30U | 140 | 2094 | 51 | 5990x1800x1600 | ||||

| XZ160/1250-30U | 160 | 2381 | 58 | 6450x1800x1600 | ||||

| XZ180/1250-30U | 180 | 2669 | 65 | 6905x1800x1600 | ||||

| XZ200/1250-30U | 200 | 2965 | 72 | 7360x1800x1600 | ||||

| XZ220/1250-30U | 220 | 3285 | 80 | 7880x1800x1600 | ||||

| XZ250/1250-30U | 250 | 3737 | 91 | 8600x1800x1600 | ||||

| XZ200/1500-30U | 200 | 1500x1500 | 3025 | 49 | 0.6 | 7.5 | 6400x2200x1900 | |

| XZ250/1500-30U | 250 | 3739 | 61 | 7225x2200x1900 | ||||

| XZ300/1500-30U | 300 | 4413 | 74 | 8130x2200x1900 | ||||

| XZ350/1500-30U | 350 | 5210 | 86 | 8570x2200x1900 | ||||

| XZ400/1500-30U | 400 | 6007 | 99 | 9880x2200x1900 | ||||

| XZ450/1500-30U | 450 | 6743 | 111 | 10820x2200x1900 | ||||

| XZ500/1500-30U | 500 | 7478 | 123 | 11560x2200x1900 | ||||

| XZ600/2000-30U | 600 | 2000x2000 | 40 | 12000 | 85 | 0.6 | 7.5 | 11100x3000x2500 |

| XZ700/2000-30U | 700 | 14000 | 99 | 12200x3000x2500 | ||||

| XZ800/2000-30U | 800 | 16000 | 107 | 13350x3000x2500 | ||||

| XZ900/2000-30U | 900 | 18000 | 127 | 14500x3000x2500 | ||||

| XZ1000/2000-30U | 1000 | 20000 | 141 | 15600x3000x2500 |

|

Item |

Name |

Description |

Pictures for reference |

|

1 |

Automatic cloth cleaning system |

It’s installed above the main beam of the filter press. It automatically moves as high pressure water (up to 10Mpa) sprayed out to wash the filter cloths. There are two types: single-sided and double-sided washing. The double type has brush which has better cleaning effect. |

|

|

2 |

Automatic bomb door system |

For collecting the liquid leakage from the filter cloth and filter plates, to avoid pollution and contamination of the worksite. It also prevents the filter cake from getting wet. |

|

|

3 |

Automatic vibrating system |

This device makes the cake fall off from the filter cloth easier. It is suitable for the viscous material that is difficult to fall off automatically. |

|

|

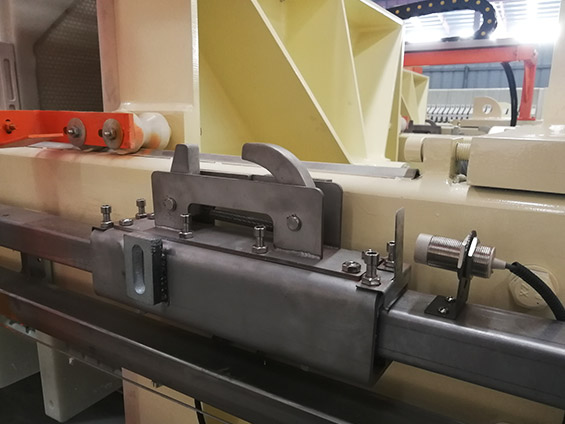

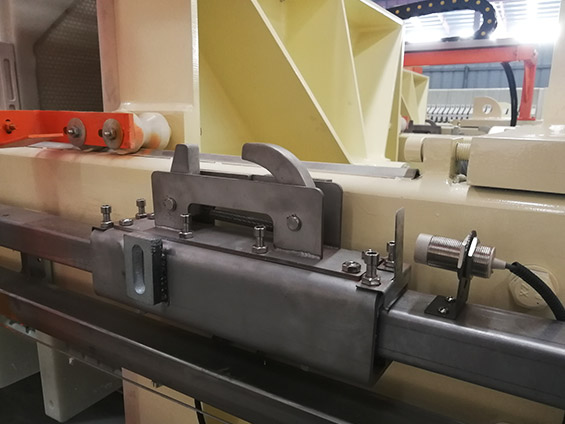

4 |

Quick open plate system |

Belong to the auxiliary discharging filter cake function. A chain is used to link all the filter plates together, so that you can open several pieces of plates at one time. It saves time, reduces labor and improves efficiency. |

|

|

5 |

Sludge storage bucket |

For easy collection of the unloaded filter cake after the separation, and convenient transportation of the cake.There are two open modes: electric type and pneumatic type. |

|

|

6 |

Belt conveyor |

Used to transport the discharged filter cake. This device is suitable for field-based work. You can put the material on the belt and it will be delivered to the designated place, reducing the labor intensity. |

|