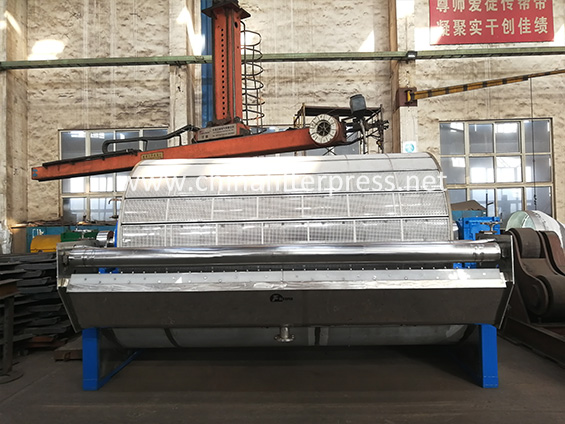

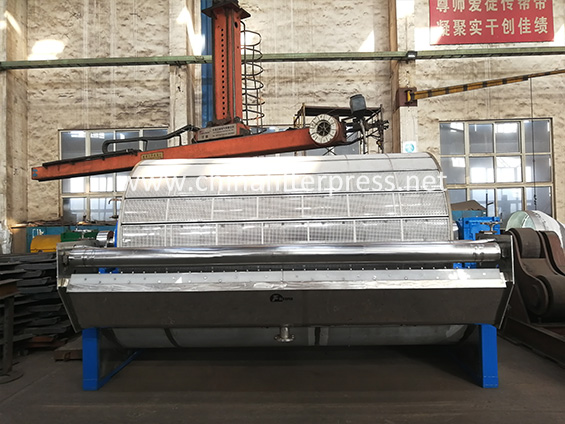

Our company is a professional enterprise producing separation machinery. The rotary vacuum drum filters we produce include three series: scraper unloading, folded belt unloading and pre-coating filtration. They are complete in models, diverse in specifications, advanced in technology, leading in the industry, high in quality, reasonable in structure, large in processing capacity, high in automation, stable and reliable in performance.

Our company is a professional enterprise producing separation machinery. The rotary vacuum drum filters we produce include three series: scraper unloading, folded belt unloading and pre-coating filtration. They are complete in models, diverse in specifications, advanced in technology, leading in the industry, high in quality, reasonable in structure, large in processing capacity, high in automation, stable and reliable in performance. They are ideal equipment for separation of suspensions. According to the unloading method, they are divided into four types: scraper unloading, folded belt unloading, roller unloading and pre-coating. According to the material, they are divided into five types: carbon steel, cast iron, rubber lining, plastic and stainless steel. The filter area ranges from 2㎡ to 80㎡ in a variety of specifications and models, and we can provide various auxiliary equipment to match them (such as automatic gas-liquid separators and vacuum pumps, etc.). We can conduct material tests and process designs for customers to meet the requirements of customers for solid-liquid separation operations on various materials.

The surface of the rotary vacuum drum filter is divided into many identical chambers, and the horizontal drum and filter cloth that are in continuous circulation operate synchronously. For any part on the surface, when it moves to a certain part of the machine, the corresponding operation is performed. For example, when it runs to the suction and filtration area, the filtering operation is performed; when it moves to the drying area, the filter cake is dried; when it moves to the unloading and filter cloth regeneration area, the corresponding functions can be performed, and then the filter cloth is led out, unloaded by the scraper, and the filter cloth is cleaned and regenerated, and then it returns to the original suction and filtration position. The drum rotates one circle, that is, a cycle, and so on. For the entire machine, filtering, washing, drying, unloading, and regeneration are in different parts. Correspondingly, different automatic operations are realized.

1. Widely applied slurry

2. High filtering efficiency

3. Easy control, strong adaptability

4. It can realize automatic continuous operation

5. Good corrosion resistance

Rotary vacuum drum filter is a continuous vacuum filtration equipment with the characteristics of continuous filtration, washing, drying, high degree of automation, small footprint, strong adaptability to materials, etc. Therefore, it is widely used in various fields that require solid-liquid separation, such as petroleum, chemical industry, metallurgy, pharmaceuticals, sugar making, starch, food, papermaking, sewage treatment, etc.

| Model | Filtration area(m2) | Drum Diameter(m) | Immersion angle(°) | Drum speed (r/mim) | Main motor power(kW) | Weight(kg) | Dimension (mm) |

| G2/1.0 | 2 | 1 | 120 | 0.13~2 | 0.37 | 1580 | 1600x1900x1500 |

| G5/1.75 | 5 | 1.75 | 120 | 0.13~2 | 0.55 | 2560 | 2200x2680x2100 |

| G10/2.0 | 10 | 2 | 140 | 0.13~0.79 | 1.5 | 4660 | 3380x3200x2170 |

| G15/2.5 | 15 | 2.5 | 140 | 0.13~0.79 | 1.5 | 5400 | 3860x3370x2750 |

| G20/2.5 | 20 | 2.5 | 140 | 0.13~0.79 | 1.5 | 6300 | 4460x3370x2750 |

| G25/2.5 | 25 | 3 | 140 | 0.13~0.79 | 1.5 | 7200 | 5160x3370x2750 |

| G30/3.0 | 30 | 3 | 90~140 | 0.13~0.79 | 1.5 | 8400 | 5100x4730x3370 |

| G35/3.0 | 35 | 3 | 90~140 | 0.13~0.79 | 1.5 | 9500 | 5530x4730x3570 |

| G40/3.0 | 40 | 3 | 90~140 | 0.13~0.79 | 1.5 | 10950 | 6100x4730x3570 |

| G45/3.0 | 45 | 3 | 90~140 | 0.13~0.79 | 2.2 | 12400 | 6600x4730x3570 |

| G50/3.0 | 50 | 3.5 | 90~140 | 0.13~0.79 | 2.2 | 13300 | 7400x4730x3570 |

| G60/3.5 | 60 | 3.5 | 90~140 | 0.13~0.79 | 2.2 | 15200 | 7600x5100x4070 |

| G70/3.5 | 70 | 3.5 | 90~140 | 0.13~0.79 | 2.2 | 19000 | 8600x5100x4070 |