Consists of two types plates, membrane plate and chamber plate.

Filtration pressure upto 10bar, reduce filtration cycle time.

Second squeeze function, reduce filter cake moisture content.

Controls of fully Automatic/ Manual as your need.

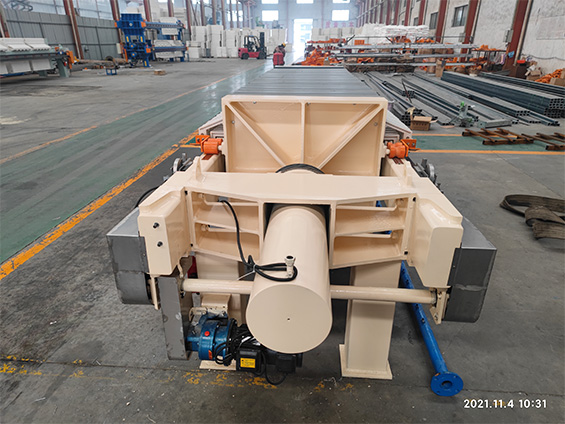

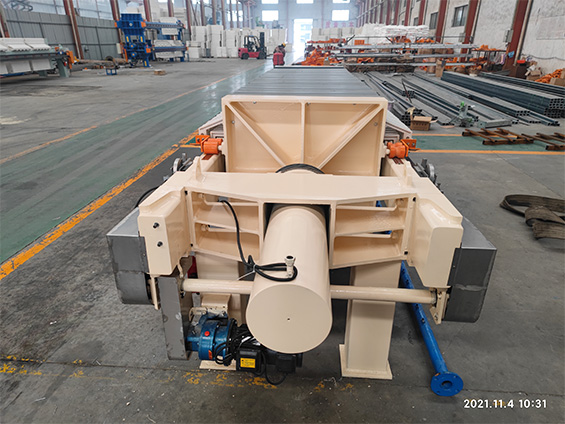

We manufacture membrane filter press matching international standards and quality. This equipment consists of membrane plate and chamber plate to form a filter chamber. The membrane plate is offered to suit up to 10 bar squeezing pressure. Due to additional liquid extraction during the squeeze cycle, solid percentages increases. Filtration cycle time are reduced compared to the conventional recessed chamber plate(Plate and frame) filter press. Conventional type filter presses are limited to using feed pump discharge pressure to produce dry solids, resulting in longer cycle times. The membrane plate reduced the long filtration cycle by introducing a squeeze medium(air or water) into the center of the membrane plate. This allows the membranes to flex against the cake, compressing it again. Filtration cycle are shorter, dry solids are increased, and waste volume is reduced.

This membrane filter press is more suitable for filtering sticky materials and users with higher requirements for moisture content. The membrane plate is made of reinforced polypropylene, which is sturdy and reliable, with a long service life, and can meet the requirements of efficient dehydration and deep dehydration.

Currently, the filter plate of filter press is made of polymer or polymer coated steel. According to the needs, the filter plate can also choose cast iron or stainless steel materials, which provide a good drainage surface for the filter cloth. The size range of the filter plate is 250 ×250 mm to 2.0 × 2.0 meters, and larger or smaller sizes are available.

Filter press usually uses filter cloth as filter medium, which is made of polypropylene filter cloth, non-woven fabric, cotton cloth, etc. filter paper board, cotton pulp board or filter membrane can also be used as filter medium as required. Generally, the cake thickness of plate and frame filter press can reach 50 mm, but in extreme cases, it can be increased to 200 mm. The box filter press (concave filter press) can form a filter cake with a thickness of 30-40mm.

Before using the filter press for filtration, if the solid suspension has precipitated, the mixed liquid needs to be pretreated, which can improve the performance of the filter press because it increases the porosity of the filter cake, thus speeding up the filtration speed. The size of floc can be controlled by changing temperature, concentration and pH value. In addition, if the filter cake is impermeable and not conducive to the flow of filtrate, filter aids can be added in the pretreatment process to increase the porosity of the filter cake, reduce the resistance of the filter cake and obtain a thicker filter cake. However, the filter aid needs to be able to be removed from the filter cake by physical or chemical treatment. A common filter aid is diatomite, with a porosity of 0.85.

Shorter cycle time

Increased dry solids

Reduced filtration time

Easily replaceable

Increased capacity

Lower waste disposal cost

Lower operating cost

Higher quality and valued end product

Widely used in coal, chemical industry, metallurgy, electric power, papermaking, non-ferrous mining and food, sewage treatment and other industries, solid-liquid separation, especially suitable to use in the flotation plant, coal, raw coal slime flotation tail solid-liquid separation dehydration.

To suitable for clients different levels of automation required, we provide the below automatic devices to choose.

1.Auto plate shifting device, after the cake forms, to open the plates one by one automatically.

2.Filter cloth auto varicose, help the cake to discharge more easily.

3.Automatic drip tray, collect the small leakage and avoid pollution in the work site.

4.Automatic cloth washing system, clean the cloths based on need.

5.Belt conveyor, better to collect the cake together.

| Type | Filter area(m2) | Filter plate size(mm) | Filter cake thickness (mm) | Filter chamber volume(L) | Filter plate number(PCS) | Filtrating pressure(MPa) | Motor power(KW) | Weight(Kg) | Dimension(mm)(L×W×H) |

| XG30/870-30U | 30 | 870×870 | 30 | 427 | 23 | 0.6 | 4 | 2680 | 3490×1250×1300 |

| XG40/870-30U | 40 | 534 | 29 | 3050 | 3880×1250×1300 | ||||

| XG50/870-30U | 50 | 676 | 37 | 3465 | 4400×1250×1300 | ||||

| XG60/870-30U | 60 | 818 | 45 | 4003 | 4920×1250×1300 | ||||

| XG70/870-30U | 70 | 960 | 53 | 4584 | 5240×1250×1300 | ||||

| XG80/870-30U | 80 | 1103 | 61 | 5082 | 5760×1250×1300 | ||||

| XG50/1000-30U | 50 | 1000×1000 | 665 | 27 | 0.6 | 4 | 4352 | 4270×1500×1400 | |

| XG60/1000-30U | 60 | 808 | 33 | 4480 | 4770×1500×1400 | ||||

| XG70/1000-30U | 70 | 950 | 39 | 5263 | 5130×1500×1400 | ||||

| XG80/1000-30U | 80 | 1093 | 45 | 5719 | 5560×1500×1400 | ||||

| XG100/1000-30U | 100 | 1378 | 57 | 6555 | 6410×1500×1400 | ||||

| XG120/1000-30U | 120 | 1663 | 69 | 7466 | 7260×1500×1400 | ||||

| XGZY80/1250-35U | 80 | 1250×1250 | 35 | 1364 | 29 | 0.6 | 5.5 | 10900 | 4830×1800×1600 |

| XGZY100/1250-35U | 100 | 1680 | 37 | 11750 | 5440×1800×1600 | ||||

| XGZY120/1250-35U | 120 | 2092 | 45 | 12600 | 6060×1800×1600 | ||||

| XGZY150/1250-35U | 150 | 2547 | 55 | 13620 | 6820×1800×1600 | ||||

| XGZY160/1250-35U | 160 | 2729 | 59 | 14470 | 7130×1800×1600 | ||||

| XGZY200/1250-35U | 200 | 3457 | 73 | 15320 | 8200×1800×1600 | ||||

| XGZY240/1250-35U | 240 | 4093 | 89 | 16170 | 9420×1800×1600 | ||||

| XGZY250/1250-35U | 250 | 4276 | 91 | 17020 | 9570×1800×1600 | ||||

| XGZY200/1500-35U | 200 | 1500×1500 | 3922 | 49 | 7.5 | 26120 | 7140×2200×2000 | ||

| XGZY250/1500-35U | 250 | 4463 | 61 | 26930 | 7730×2200×2000 | ||||

| XGZY300/1500-35U | 300 | 5274 | 73 | 28160 | 8720×2000×1820 | ||||

| XGZY350/1500-35U | 350 | 6221 | 85 | 29600 | 10110×2000×1820 | ||||

| XGZY400/1500-35U | 400 | 7032 | 99 | 31500 | 11260×2000×1820 | ||||

| XGZY450/1500-35U | 450 | 7844 | 111 | 33400 | 12250×2000×1820 | ||||

| XGZY500/1500-35U | 500 | 8791 | 123 | 33380 | 13240×2000×1820 | ||||

| XGZY600/2000-40U | 600 | 2000×2000 | 40 | 12000 | 85 | 54164 | 13030×3520×2500 | ||

| XGZY700/2000-40U | 700 | 14000 | 99 | 58300 | 14390×3000×2500 | ||||

| XGZY800/2000-40U | 800 | 16000 | 107 | 62460 | 15770×3000×2500 | ||||

| XGZY900/2000-40U | 900 | 18000 | 127 | 66620 | 17150×3000×2500 | ||||

| XGZY1000/2000-40U | 1000 | 20000 | 141 | 70780 | 18530×3000×2500 |