Filter cloth is the important part fot filter press. If a filter press want a best performance, it’s mainly depended on the separationnature of the filter cloth. According to the material, filter cloth can be divided into two types: one is nature fibers, such as cotton. Woollens, silk, liner etc.; the other is synthetric fibers, such as dacron, nylon, polyacrylonirile, vinylon, acrylic fibers, polyester fibers etc.

Filter cloth is the important part fot filter press. If a filter press want a best performance, it’s mainly depended on the separationnature of the filter cloth.

According to the material, filter cloth can be divided into two types: one is nature fibers, such as cotton. Woollens, silk, liner etc.; the other is synthetric fibers, such as dacron, nylon, polyacrylonirile, vinylon, acrylic fibers, polyester fibers etc.

According to yarn, it’s divided into 3 types, monofilament yarn, multifilament yarn, spun yarn. The monofiament is not easy to cause block and good at cake discharging, the multifilament yarn has high strength, and also good at easy dischargeing and renewable performance, the spun yarn is good at solid capture and have better sealing performance.

1. Various specifications, processing and customization services are available

2. Good filtering effect and long service life

3. Low price

Filtering speed: Plain weace

Filtrate clarity: plain weace

According to producing method, the filter cloth divided into following types:

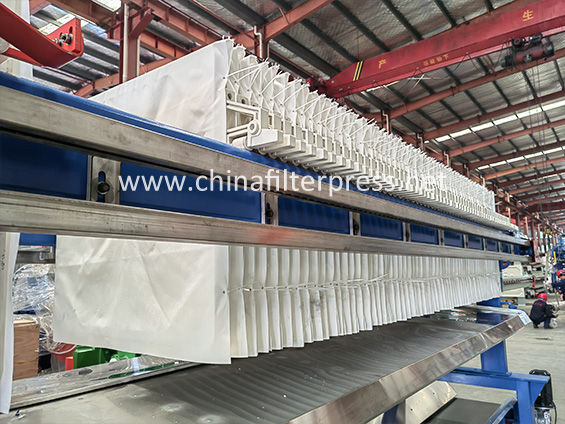

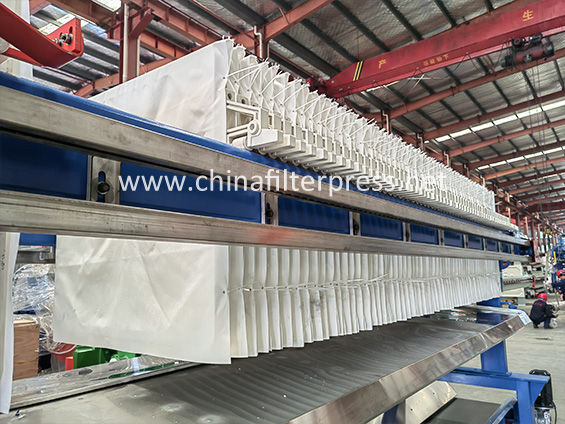

Chamber ilter cloth, plate & frame filter cloth, multilayer filter cloths etc. the cloth fixing method can use: cloth belt, ties, clamps etc.

According to different industrial needs, the filter cloth can be specially processed: latex coating, gasket receeed ect.

Installed on the filter plate, used with filter press. Widely used in smelting, chemical industry, environmental protection, pharmaceutical, sugar, petroleum, ceramics, food, mining, aerospace and other industrial sectors.